November 2, 2017

Since we first launched our FRESHQ® portfolio, it has swept the global dairy industry off its feet for its outstanding protective properties against yeast and mold in an all-natural way – well in line with a strong consumer preference for a clean label.

Now the well-oiled innovation machine has done it again: developed a series of new second-to-none FRESHQ® cultures that protect even better against especially yeast, and which can withstand small breaks in the cold chain on the, sometimes, long way from producer to consumer.

FRESHQ® second generation is ready to take over from its predecessor, thereby making the best better.

Only few strains made it through the eye of the needle

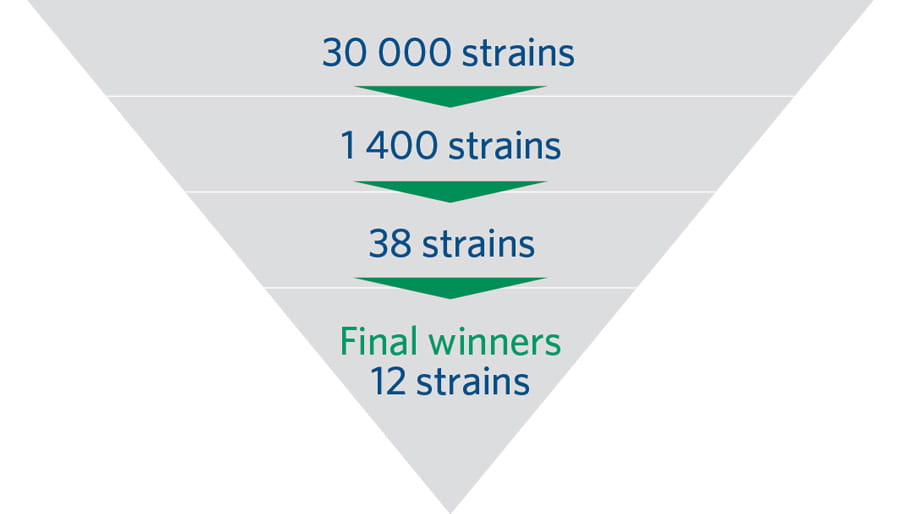

From a starting point of 1400 bacterial strains, taken from our impressive collection of more than 30,000 strains, only 12 passed the strict selection criteria to make it into actual application trials. And from those, a handful of unique strains ended up as the chosen few that have been combined into the series of seven new FRESHQ® cultures for yogurt, mesophilic applications like sour cream, kefir etc. and white cheeses.

“When developing these new cultures, all the trials had to take place within the dairy product itself, all the way from our advanced robotic equipment in high throughput analyses, to the compounding of strains and final application validations. Selection of the best strain candidates is very complex because all the food culture strains interact with each other and the milk in the dairy product during fermentation; that is why we can’t use lab substrates or media to grow these cultures; it would give us misleading test results,” she elaborates.

Significantly improved

Needless to say, this results in a longer process – but it was indeed worth the wait:

“FRESHQ® second generation has overcome some of the limitations we have identified in the first generation. It is significantly improved on the protective effect against yeast and molds, which is very useful – for instance in situations where dairies want to provide consumers with products without artificial ingredients.

In the development of the cultures we have also focused on selecting strains that have a minimum impact on the process and help obtain the desired flavor. FRESHQ® 2nd generation includes unique cultures causing a minimum of additional post acidification during storage which translates into the advantage that the acidity or taste is not affected even if the cold chain is occasionally broken.”

Tina Hornbaek however stresses that bioprotection is not a “silver bullet” that magically fixes everything: “Bioprotection is an additional measure that can be added on top of other preventive actions, like a strict hygiene standard in food production facilities.”

Along with the Product Development track we have made significant progresses on our bioprotection competences in close collaboration with other departments throughout the entire product development value chain, including:

- Development of robotized high throughput screening assays, based on inhibition of the target organism in the real dairy application

- Building advanced application competences through insight into the complex interaction of the bioprotective cultures, the dairy product and the production processes

- Learning how strain media and formulation have a major impact on the final product performance

Mode of action

In short, FRESHQ® natural food cultures work by a combination of mechanisms that counter harmful microorganisms in the dairy product, including:

“We are very pleased with the second generation solution, which renders even stronger protection and offers better ability to maintain the desired product flavor. Now we have a better palette of antifungal cultures, and that gives access to more markets and new discussions with customers,” concludes Tina Hornbaek.

She enjoys working in an area of such a high strategic focus to Chr. Hansen: “It’s demanding – but also great fun and rewarding to work in Bioprotection, which is a strategic lighthouse in our overall strategy and highly prioritized by top management – you really understand how you contribute to the company’s goals every day!” she smiles.