Industry challenge

Regardless of producer size and type of cheese, the milk gel-cutting step is often the least controlled step in the cheese making process. A large part of the overall cheese yield, however, depends on this critical step making it essential to be able to measure and control the process. Many cheese manufacturers have had to resort finger palpation, a technique with known disadvantages such as the inability to perform the test in real time and scarcity of experienced cheesemakers. This method is also subjective and not quantitative.

Our solution

In partnership with Rheolution Inc., a Canadian-based process control and analytics company, Chr. Hansen now offers a data-based solution for measuring and controlling your coagulation process. COAGUSENS™ tells you the exact firmness value you cut the curd at. Experimenting with cutting at lower and higher firmness values and correlating with the resulting yields allows cheesemakers to target the right cutting firmness and to reach the highest yield, step by step.

COAGUSENS™ is the first process instrument located near (but outside) the vats that delivers accurate and real time measurements of milk coagulum firmness. COAGUSENS™ was designed with cheesemakers for cheesemakers.

Case study

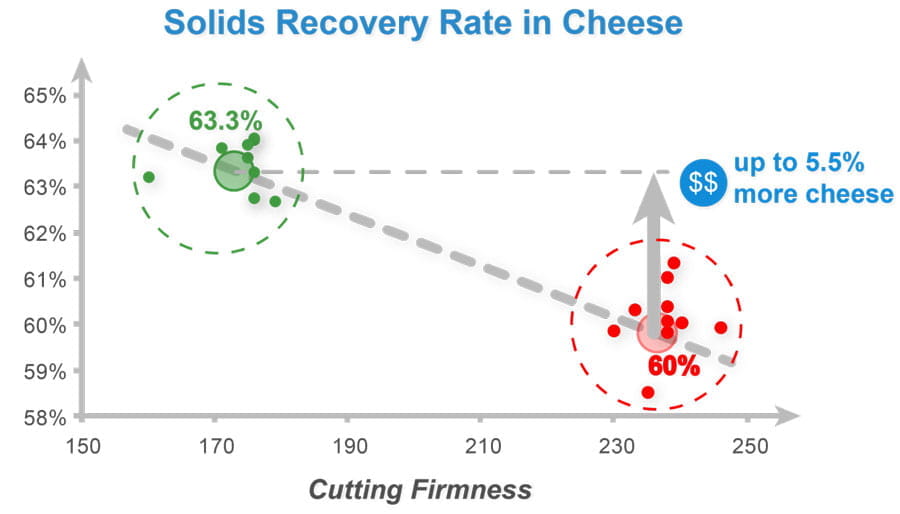

In a North-American cheese plant, COAGUSENS™ was used to monitor the coagulation of 37 cheddar batches. Located near coagulation vats, COAGUSENS™ measured curd firmness in real-time and recorded firmness at cut for every monitored batch. Firmness is measured in pascal units (Pa): the more pascals, the firmer the curd.

The solids recovery rate was calculated from tank milk solids and whey solids, both measured with a Near Infra-Red (NIR) milk analyzer.

Solids Recovery Rate (in %) = (Solids Weight in Milk – Solids Weight in Whey) / Solids Weight in Milk.

Data shows that solids recovery rate is a much better coagulation performance indicator than yield that is influenced by cheese moisture and all the process steps following coagulation.

Production managers at the plant used COAGUSENS™ to assist their decision on when to cut. They initially targeted 235 Pa for which solids recovery rate averaged 60%. When they targeted 170 Pa, the solids recovery rate increased to 63.3% resulting in a yield improving from 14.6% to 15.4%.

Every 35,000 Lbs milk vat delivered 5,124 Lbs cheese at 60% solids recovery rate and 5,407 Lbs at 63.3% solids recovery rate. COAGUSENS™ therefore made it possible to generate 282 Lbs more cheese per vat.

At this particular cheese manufacturer, rather than relying on processes to recover lower value reprocessed whey ingredients, profitability was increased by using COAGUSENS™ to help with conversion of milk solids directly into cheese.